BLOG

2019.09.20 update

LEAF SPRING AND AIR SUSPENSION

The suspension that supports the truck is a very important part that significantly affects the characteristics of the truck, so the type and condition of the suspension are important points to check when buying a used truck. Today we explain the difference between the leaf spring and the air suspension.

Leaf spring

Leaf spring is a type of suspension composed of spring plates with different lengths which is assembled near front/rear wheels of vehicles to be able to carry heavy objects.

However, trucks which are produced lately is mainly installed a different type of spring called air suspension because it is uncomfortable to drive trucks with leaf spring. But leaf springs are still used on heavy commercial vehicles such as vans and trucks due to its durability.

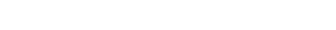

Structure of leaf spring

Do you know how leaf spring works?

Leaf spring consists of multilayered spring plates. The longest spring called main spring is attached to chassis supported by shackles.

Leaf spring makes it possible to absorb impact and vibration from a wheel by bending the spring plate. There are two types of name for the leaf spring. One of them is called ‘over slung’ when the leaf spring is putted on the upper side of the axle. The other one is called ‘under slung’ when the leaf spring is putted under the axle. The place to be putted the leaf spring depends on the vehicle type.

Advantages and disadvantages of leaf spring

ADVANTAGES

・It can bear heavy loads

・Not expensive to repair comparatively

The material of leaf spring is made of steel so that means it is very strong and withstand heavy load. Also, it is cheaper to maintenance than the other suspension as the structure is simple.

DISADVANTAGES

・Not comfortable to ride

・It can be damaged easily

It is not comfortable to ride in, and it could jump you up when you hit a step because leaf spring is made of steel.

However, the cost to repair will be much cheaper than air suspension, so leaf springs are still used on heavy commercial vehicles such as vans and trucks.

Air suspension

Air suspension absorbs shocks from the road surface with a rubber cushion filled with high-pressure air. It is used for sightseeing buses that require high suspension functions and habitability, and transport vehicles for precision equipment.

Advantages and disadvantages for air suspension

ADVANTAGES

・Reduction of vibration

・An adjustment of the vehicle height

Air suspension always demonstrates high shock absorption capacity regardless of the load weight and give us a comfortable ride.

DISADVANTAGES

・Expensive to maintain

・Air leakage

Due to the structure of the air suspension, it generates air leakage, and periodic inspections and repairs are required.

Although there is a difference between a leaf suspension with a simple and primitive structure and a high-performance air suspension, both suspensions satisfy the functions of the suspension aimed at absorbing shock from the road surface and suppressing vehicle tilt. It can be said that the suspension should be selected depending on the cargo to be transported.

Check our stock: https://yamada-co.jp/en/

---------------------------------------------------------------

Japanese Used Trucks & Machinery Exporter

Yamada Sharyo Co., Ltd.

Website / Contact Us / About Us

Search Trucks / Search Machinery

---------------------------------------------------------------

- LATEST ARTICLES

-

-

2022.04.05

Mitsubishi Fuso Truck and Bus Corporation Introduces New "Euro 4" Compliant Lineup to Indonesian Market

-

2022.03.22

We Opened Facebook Page and Instagram!

-

2022.03.08

Recent Best Sell!

-

2022.02.22

Japanese made excavator brand ‘YANMAR’

-

2022.01.05

Special Announcement ~AUCTION & EXPORT SERVICE STARTS!~

-

- CATEGORY

- ARCHIVES

-

- 2022-04(1)

- 2022-02(1)

- 2022-03(2)

- 2022-01(1)

- 2021-01(2)

- 2021-06(2)

- 2021-03(1)

- 2021-09(1)

- 2021-07(2)

- 2021-08(1)

- 2021-12(4)

- 2021-11(1)

- 2021-02(2)

- 2021-05(3)

- 2021-10(2)

- 2021-04(3)

- 2020-04(8)

- 2020-02(4)

- 2020-01(4)

- 2020-07(4)

- 2020-05(3)

- 2020-12(2)

- 2020-08(3)

- 2020-10(3)

- 2020-06(6)

- 2020-09(3)

- 2020-03(5)

- 2020-11(2)

- 2019-01(3)

- 2019-12(4)

- 2019-08(3)

- 2019-11(5)

- 2019-04(7)

- 2019-02(4)

- 2019-05(4)

- 2019-06(4)

- 2019-07(3)

- 2019-09(4)

- 2019-10(4)

- 2019-03(3)

- 2018-02(4)

- 2018-05(4)

- 2018-06(7)

- 2018-10(4)

- 2018-07(4)

- 2018-11(5)

- 2018-09(4)

- 2018-08(4)

- 2018-03(5)

- 2018-12(3)

- 2018-04(6)

- 2018-01(4)

- 2017-12(8)